The mark of a professional electrician is that he upgrades his tools based on latest industry standards.

He keeps himself up-to-date with current news about technologies in the field and tries to incorporate them into his own work.

Anyone can go around with a multimeter but only a proficient electrician will carry and know how to use a clamp meter.

Clamp meters have been around for years and yet most electricians still depend on the humble multimeter for current measurements.

But, it is high time now that you understand what they are capable of and make one a part of your toolkit.

Owning a clamp meter is like having a certification; it automatically elevates your image as an expert.

Here’s a little story that shows the trait of an expert.

When I was a child, a technician was called in to repair our desktop computer.

The man checked the system, opened the CRT monitor screen, and tested few PCB lines and components using his multimeter.

A few minutes later, he soldered few lines or components together (not sure which at that time as I was years away from my Electronics Engineering degree) and closed the monitor.

It worked.

The job seemed so effortless that I suspected if the guy had even done anything.

So, when he told what the repair had cost us I asked him why such a heavy price as I could have done it myself.

He replied, “But, did you know where to solder?”.

And I was floored.

Knowing what you’re doing and using tools that the rookies don’t know about is what sets an experienced electrician apart.

And that is the reason why we will be going through the importance of clamp meters today.

What is a Clamp Meter?

A clamp meter is a type of electrical meter that allows measurement of alternating current (AC) (and sometimes direct current (DC)) without the need of contact with the conductor (wire or cable) or disconnection of the unit/system.

It comes with two jaws (that form a ‘clamp’ around the conductor) that can be adjusted around a wire or a cable to gauge the current running through a circuit in real time.

How Does A Clamp Meter Work?

A clamp meter uses its jaw-like structure to detect and gauge the magnetic field that is generated by the current as it flows through a conductor at a given time.

The clamp consists of a ferrite rod with windings that works on “transformer action” to detect magnetic fields and then measure current.

It can only detect and concentrate a field created by a single conductor at a time.

This is the reason why a clamp meter can only measure current through a single probe (where the direction of current is unidirectional).

Also known as a clamp-on ammeter, today’s models (modern variations) can measure several quantities when equipped with additional instrumentation.

Highlights of a Clamp Meter

Two of the biggest reasons why electricians prefer clamp meters over traditional ones are:

- The ability to measure current without touching a live conductor

- Does not require the circuit (of which current is being measured) to be switched OFF

There are many more features and functions that a clamp meter is capable of. More on this in the following section.

Functions of a Clamp Meter

The main reason why a clamp meter is preferred in industrial and HVAC environments is that it can measure high ranges (above 10A and up to 1000A) of current magnitude.

Your general-purpose tester will break down if it tries to measure 10 amperes for 30 seconds or more.

This way, it is eligible to be used for servicing, maintenance, and installation.

Transformer Action

In a clamp meter, the primary role is carried out by the ferrite core which acts as a secondary winding (of a transformer).

The current that is detected in a conductor is coupled into this secondary winding which is connected to the shunt of the tester’s input.

As per transformer action, a small amount of current is delivered to the input of the meter, which makes it easier for it to detect large currents.

Visualize how a step-down transformer works and that’s basically what happens in a clamp meter. In general, the secondary winding detects 1/1000th of the current that is flowing through a conductor.

Therefore, when you measure one ampere of current, the meter actually detects one milliamp, which is then converted and shown in the display.

Hall Effect (for DC Measurement)

A clamp meter measures DC using the principle of Hall Effect.

A chip capable of sensing the strength of magnetic flux is attached between the jaws (the clamp formation) for this purpose.

Most clamp meters today are equipped with this feature.

What Quantities Can a Clamp Meter Measure?

While the main idea of a clamp meter is to measure AC and DC, it can also detect and gauge the following electrical quantities (yet not limited to):

- Resistance

- Capacitance

- Temperature

- Frequency

- Phase (wave forms)

Types of Clamp Meters

There are four primary types of clamp meters based on their peculiar functions. They are listed below:

- Current Transformer Clamp Meter – Capable of only measuring AC, this is the original type

- Hall Effect Clamp Meter – Can measure both AC and DC quantities. Most modern clamp meters that are available in the market today are of this type

- Rogowski Coil – A special type of clamp meter which uses a helix-shaped flexible coil without a ferrite core inside to measure AC. A perfect choice for when you need to reach tight spaces (e.g.: three phase unit of a building)

- Iron Vane Clamp Meter – A moving iron vane is used to measure true RMS value. It can measure both AC and DC but is an obscure meter used only in heavy industries.

In addition to these four, there are several variations that are available.

For example, a multimeter fitted with a plug-in clamp is one type. Advanced clamp meters also exist with which you can measure inrush current and variable frequency.

Find a good clamp meter with this ultimate clamp meter reviews.

Clamp Meter vs. Digital Multimeter

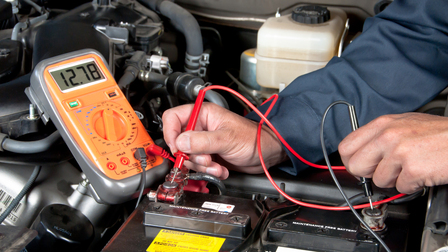

A digital multimeter (DMM) is a general-purpose testing tool that measures a variety of quantities like voltage, resistance, and current.

Whereas, a clamp meter, although capable of measuring these quantities, focuses on current.

It can measure high magnitudes of current (up to 1000A) which a basic DMM cannot handle. (For this, there are HVAC DMMs available in the market.)

A DMM usually can give high-resolution reading, often measuring in milliunits, but a clamp meter will only detect up to a hundredth of a unit. While this is enough for electrical purposes, it can be a limitation when used in electronic circuit testing.

A clamp meter is preferred because it can measure current without the need to switch OFF the system/circuit.

In the case of a DMM, you have to disconnect the circuit from the power supply and use probes and cables. This can be dangerous when working in high energy environments.

As it is clearer now, a clamp meter takes safety into consideration above everything else, and owning one shows thought and pragmatism.

Having noted the main differences, it makes sense for an electrician to own both a DMM and a clamp meter.

Troubleshooting requires you to detect several quantities and an expert electrician can never be low on his tools.

Read more:Top-rated Multimeter Reviews

How to Choose the Best Clamp Meter?

Here’s what can fluster even the most experienced electricians: finding the ideal clamp meterthat works for his needs.

It’s even more frustrating because there are so many great models, types, and listings online that you could exhaust one whole day just making your pick.

Buying an ideal clamp meter should depend on factors like accuracy, functions and features, and resolution and durability.

Prominence should be given to the environment where the meter will be primarily used in.

In any event, it’s best to base your selection on these seven important factors:

1 - Accuracy and Precision

This is unarguably the most important factor when it comes to selecting the perfect clamp meter. You don’t want to have a tester that also detects nearby noise and adds it up to the final reading.

Make sure the meter gives true RMS reading by testing it. (If you purchase online, test your meter the first thing you receive it)

You also want your meter to repeat accurate results even after years of use. So, pay attention to the calibration and if your meter requires being calibrated every now and then.

2 - Environment

This is the second-most important factor because unlike a digital multimeter, a clamp meter is used for specific work in specific environments.

You want your meter to be capable of withstanding high temperatures or static atmospheres. Therefore, a good look at the functions is absolutely necessary.

3 - Functions

A clamp meter that only measures AC is useless for a technician who works on electronic circuits.

It is important to buy a meter that takes care of all your needs.

Have a look at the different types of clamp meters above and make your base choice

4 - Meter Body

It has to be rugged enough to withstand shocks and falls because you never know when it is going to slip from your gloveless hands (sorry!)

5 - Meter Rating

Using a clamp meter that is rated for 500A to test anything above that is borderline dangerous. It can not only harm the meter but also give you a shock, which can be fatal.

Safety is always the top priority, so get a meter that is rated higher than your actual requirements

6 - Features

The ability to check waveforms in real time sounds good but not essential. So, while having a bunch of usable features is recommended, do not focus on the quantity more than the quality.

Nowadays, brands cram all sorts of features and functions into a single unit to increase the price and thereby compromise on the accuracy and reliability of the device.

So, choose a meter that is known for greater accuracy than it is for its features.

7 - Brands

There are brands that are popular and trusted and there are brands that are not. So choose wisely and ideally go with a brand that you trust

This list of factors is not exhaustive and is only meant to give you a basic idea as you make your final purchase. Parameters like price, weight, and usability can also be considered.

Tips to Find Your Right Meter

Get ahead yourself and expedite the selection process by trying to answer the following questions.

What we suggest is to jot down the answers to these questions in a piece of paper and then check out the best clamp meters available online.

Question set –

- Where will you use your clamp meter? (Outside or only indoors?)

- Does your meter give true RMS reading? (Error margin of less than 5%)

- Do your tools last longer based on your use? (Rough use)

- What are the quantity ranges that you intend to measure if you work on only specific projects?

- What are the three main features that you cannot do without? (High resolution, big display, backlight, etc.)

- What size is ideal for you? (Pocket or large?)

See also:How to Choose the Best Rotary Tools?

Useful Tips for Using Clamp Meters

The following is a list of 8 useful tips that you can use to take full advantage of your new clamp meter:

1 - While measuring current using a clamp meter, always take multiple readings with intervals of a few minutes. This is because the dynamic nature of current

2 - Do NOT use both the clamp (jaws) and the probe wires at the same time

3 - When measuring using the jaws, keep your fingers behind the barrier (tactile) of the meter

4 - Replace the batteries as soon as the ‘low battery’ indicator appears. Always carry spare batteries

5 - It is NOT recommended to use the clamp meter around bare conductors. Under no circumstance should this be allowed or practiced

6 - When using a flexible meter, always use insulation gloves and do not switch ON the meter until you have connected the helix cord

7 - If you use the meter to measure multiple quantities, it is a good idea to get them calibrated once every six months

8 - Always wear industrial hand gloves while operating a clamp meter in high energy environments. Although clamp meters are heavily insulated, it is always better to take precaution.

Conclusion

I hope that the above guide has helped you understand the basics of a clamp meter. The tips for buying and using your meter will ensure that you get accurate readings without compromising on safety.

You may also check out our buying guide to make your selection process easier.

Good luck your new device!